Techno-Labo is a company which supports the development of plastic products by design, mechanical engineering, prototyping, and low volume production.

In a recent trend, to develop a product, the small market has been spotlighted that can flexibly meet users’ requests. It seems LVP is replacing mass-production society.

Techno-Labo is offering services to support LVP in this market.

Although 3D printers attract much attention for low initial costs, it seems quite challenging to manufacture saleable merchandises due to a low quality of appearance form, a fragility of material, and high cost per unit.

In the case of LVP, injection molding is the only choice as well, but initial costs will be an enormous pain due to mold cost.

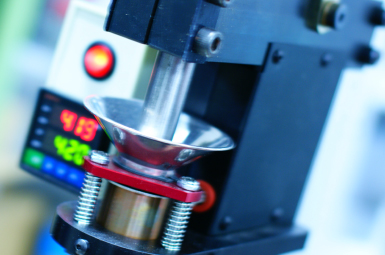

We have abundant know-how to make cassette-molds, which is a sort of substitute-molds. We mainly have the expertise to make cassette-mold using aluminum and inexpensive resin. It hugely decreases initial costs, even if you manufacture your product by injection molding.

Even if you can make a mold with reasonable cost, you cannot find a manufacturer for mass-production if the total quantity is small. They need more than a certain amount of order price to operate their factory.

We are using substitute-molds, especially cassette-mold. It allows factories to manufacture various kinds of products without exchanging mold-bases. Even though each cassette-mold manufactures a small volume of products, it will be high through manufacturing with some quantities of cassettes-mold. Factories can comfortably work with this method.

As a result, you can secure the manufactures for LVP.

The same equipment and systems of mass-production will be necessary if we try to make products with the same quality as mass-produced goods. To realize LVP on a limited budget, you should set appropriate quality for each product.

Since the in-house designers are designing appearance form and mechanism of products, we can set an appropriate quality level. Moreover, we are studying numerous products on the market.

At the phase of mechanical design, we are reviewing potential issues that may occur while manufacturing. Also, we are organizing a quality assurance system suitable for LVP. Therefore, we can maintain a quality of products even for LVP.

Usually, the quality criteria are not consistent in the case of LVP, so the risk of defects flowing to customers will increase, and it will be tough to commercialize. Utilizing Techno-Labo's system, we can keep the quality of our products as high as a standard of Japanese assembling company that is famous for strict inspection. Then we can provide plastic parts to the market.

These systems of design and LVP are realizing Techno-Labo’s service to create new products from small quantities.