Techno-Labo is a company which supports the development of plastic products by design, mechanical engineering, prototyping, and low volume production.

Plastic products are considered cheap. However, molds are essential for producing plastic products. Plastic has a characteristic that the initial cost, which is the mold cost, accounts for the majority of the development cost. Low-cost plastic products use highly durable, high quality and expensive molds, and the initial cost has been depreciated by mass production.

When production quantity is small, active product development cannot be achieved with the same price mold. Therefore, Techno-Labo offers substitute mold optimized for LVP. It can reduce the initial cost that is a major obstacle of LVP. We realized to offer sufficient quality of mold with a reasonable price.

Normal molds require too much initial investment in these cases: “Need customer evaluation using 200 units of prototypes before mass-production.”; ”500 units are enough volume to meet the needs of limited users.”; “Not aim to manufacture one product for 10,000 units, but want to make various shape of the products for 200 units.” Unlike usual mold, substitute mold can save the total cost in case of making less than 1,000 units because its initial investment is low and product price is high.

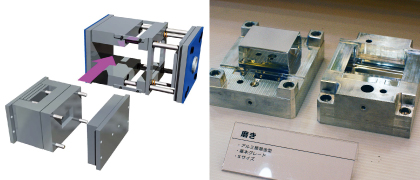

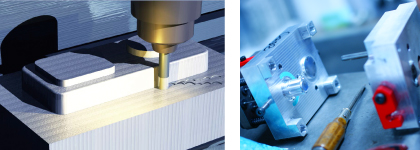

Techno-Labo utilizes a cassette type aluminum mold to make products. We also offer fixed pricing which helps the beginners of manufacturing to make a budget easily.

Prepare mold base on a machine, then install removable cassette mold to it. It halves total cost because it is easily made, replaced, kept and mold bases are compatible with other cassette molds. The disadvantage is that it cannot make products bigger than mold bases.

Make a mold from aluminum alloy. The delivery time is short due to the ease of cutting. However, the maximum shot is from 500 to 1,000. It also has a disadvantage such as getting scratch easily.

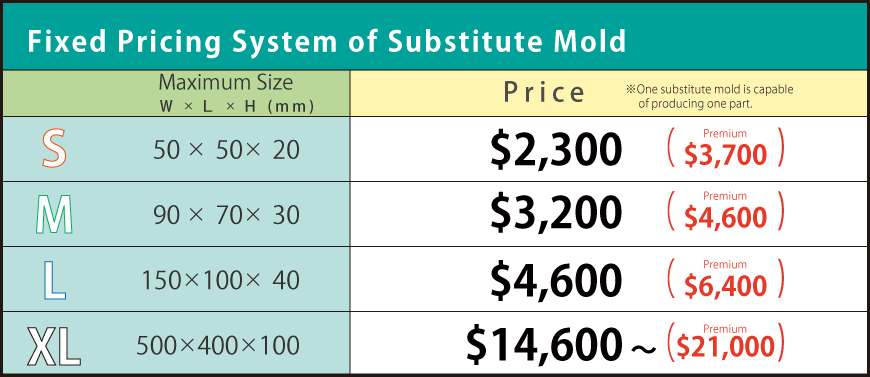

○Clear pricing service of substitute mold optimal for LVP (less than 500 sets)

○Pricing is fixed based on the dimensions

○More beneficial for a larger product. Reduce the total cost.

○Offer two types of grades according to required product precision

Applied the below pricing since April 11, 2016.

Only Techno-Labo is offering fixed pricing service about the injection molding of resin. 3D CAD data is required to this service.

Offering design and mechanical engineering service as well.

Premium grade is applied to the molds with a fitting curved surface. (Basic grade: case type)

○Sensor case

(133×62×16mm)

○Remote controller with display

(155×115×61mm)

○Transparent tag case

(45×45×7.5mm)

・Because we are a company with extensive know-how in creating simplified molds inexpensively.

・We also effectively utilize overseas manufacturers.

・Mold sales are not our primary business, so it's okay if we don't make a profit from mold production.

・We handle far more jobs than other manufacturers, allowing us to operate on thin margins.

・Our aim is to be a strong supporter behind the scenes: if your company thrives, it benefits us with more work!

・The accuracy is sufficient depending on the application and usage environment. Please refer to the photos of our case studies for more details.

※However, it is not suitable for mechanical parts requiring numerous dimensional tolerances.

・Primarily intended for cases and similar applications, we have a track record of success. There are no issues with the fit.

・We mainly serve small and medium-sized enterprises and individuals.

・We often receive inquiries from companies that have raised funds through crowdfunding.

・Many of our clients are companies involved in electrical system development.

・Our focus areas include wireless devices, labor-saving equipment, medical devices, and welfare-related products.

・We frequently receive inquiries from clients who do not have prepared design drawings.

・Recently, we have seen a significant increase in requests for IoT devices.

In short, it's because they are made under the premise of producing 'a lot of good quality items'. Standard molds are designed with the expectation of producing 100,000 pieces, and in some cases, over a million, incorporating extensive know-how in materials, precision, and experience.

Standard molds are designed with the expectation of producing 100,000 pieces, and in some cases, over a million, incorporating extensive know-how in materials, precision, and experience.

Even minor imperfections or marks that might go unnoticed by a layperson are not tolerated.

Naturally, this requires skilled technicians (who command higher salaries) to put in thorough consideration and use expensive machinery to produce the mold.

Although it is with some hesitation to say this as the party receiving your business, we have compiled below some important considerations regarding the technical aspects, transaction conditions, and rights involved in our dealings.

We kindly ask for your understanding in these matters. If there are any terms you cannot accept, please notify us. We will proceed with the work under the understanding that you have accepted these terms, and it will be difficult to accommodate any changes if informed later.

Durability and Maintenance

This mold requires maintenance (subject to a fee) every 500 shots. The cost of maintenance may vary depending on the product design, material used, and other factors. With regular maintenance, the mold can be used almost indefinitely. However, storage costs may apply to molds that are not used for an extended period.

Finishing Level

The surface finishing ranges from ▽▽ to ▽▽▽. We do not offer textured finishes, but we can provide a non-glossy finish through blasting for an additional surface treatment fee. Acceptable levels for imperfections such as sink marks, flow marks, and weld lines are based on typical standards for industrial equipment exteriors.

Available Materials

In principle, all common plastics can be used. However, grades with fillers cannot be used. Some engineering plastics are also compatible, but not super engineering plastics. Additionally, materials such as PVC and thermosetting resins are not compatible.

Color Matching and Special Materials

Color matching for individual products is possible, and we can also work with special materials like elastomers. Please be aware that additional costs and lead times for material procurement may apply. Also, note that color matching can be influenced by subjectivity, so the final color may not necessarily match the specified color precisely.

Quality Standards

Quality standards are determined by our company's criteria for evaluating the quality of the products. If you have specific quality criteria in place, please inform us in advance. Due to the nature of the molds, there may be cases where we cannot comply with your company's standards. Additionally, please note that we do not conduct factory audits. Thank you for your understanding.

For simplified molds, we will begin production upon receipt of your payment, regardless of whether you are a large or small-scale manufacturer. Please understand that the same conditions apply to all customers. While we do offer the option for product manufacturing through your preferred payment method, please be aware that initial transactions, especially during the first few orders, may require cash transactions. We appreciate your understanding in this matter.