Techno-Labo is a company which supports the development of plastic products by design, mechanical engineering, prototyping, and low volume production.

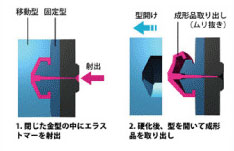

In the case of thermoplastic (moldable on heating and harden on cooling) elastomers, products can be manufactured by injection molding the same as general plastics.

In the case of thermoplastic (moldable on heating and harden on cooling) elastomers, products can be manufactured by injection molding the same as general plastics.

Thermoplastic (moldable on heating and harden on cooling) elastomers can be a material of injection molding the same as general plastics.

Elastomer stays elastic after solidified by cooling, so it is ejectable even a product has some undercuts. For prototyping, a general method is pouring elastomer into a silicone rubber mold.

Phase of low volume production

For LVP, we produce products of thermoplastic elastomers utilizing substitute molds.

There are also a few cases to produce with butadiene or isoprene for the applications of vibration isolation and shock-absorption exploiting its unique physical property.

For these cases, we pour the material into some cases and produce samples.

Phase of mass-production

For mass-production, we produce products of thermoplastic elastomers after manufacturing molds.

What is elastomer?

Elastomer is a rubbery and soft macromolecular.

It primarily means thermoplastic material compatible with injection molding. Sometimes it means material of injection molding which does not require vulcanization.

The material is widely got attention for its flexibility of composition to adjust softness, elasticity, and other physical property.

It consists of a hard segment and soft segment, and each property determines the total physical property.

・Require softness

・Direct skin contact

・Joint parts

・Shock absorption

・Recyclable (Thermoplastic)

・Vulcanization is not required, simple composition.

・Easy coloring, can be transparent

・Compoundable with other materials

Material Types

| Thermoplastic Elastomer [TPE, TPR] | ||

|---|---|---|

| Thermoplastic Styrenic Elastomer[SBC, TPS] | Thermoplastic Olefinic Elastomer [TPV, TPO] | Ester [TPEE, TPC] |

|

Popular, comparatively reasonable.

Having lightweight and outstanding flexibility and elasticity.

The product variations are classified in SBS, SEBS, SIS, SEPS based on the difference in soft segment materials. It is usually used as a modifier of PP.

Major Product: SEPTON (kuraray) RABALON(Mitsubishi Chemical) |

Popular as TSE. Thermoplastic vulcanizates (TPV) is popular for its flame retardance, but not reasonable. The hard segment of TOE is PP, so usually compounded with PP to improve recycling. Lightweight. Major Product: Thermorun™(Mitsubishi Chemical) Milastomer(Mitsui Chemical) |

It has high heat resistance and is less likely to become fragile in repeated bending and low-temperature environments. Both hard and soft segment are polyester. It is used for automobile and ski boots. Materials are slightly expensive. Major Product: Hytrel(DuPont, Toray) PELPRENE(TOYOBO) |

| TPVC | Thermoplastic Polyurethane [TPU] | Thermoplastic Polyamide Elastomer [PEBA, TPAE, TPA] |

| Very old and reasonable material which has quite good weather resistance. The hardness is freely adjustable with the amount since the soft segment consists of plasticizer and oil. The use is avoided, but the demand is still high. |

It has been used for quite a long time compared to other elastomers. It consists of polyurethane and polyester and has high abrasion resistance and elasticity, but relatively expensive. Major Product: Miractran (Nippon Miractran) |

It is soft but strong in repeated bending. It has oil and chemical resistance. The price is very expensive. The hard segment is nylon 12. Major Product: Polyamide Elastomer (UBE INDUSTRIES) |

| < Thermoplastic Elastomer [TPE, TPR] > |

|---|

| Thermoplastic Styrenic Elastomer[SBC, TPS] |

|

Popular, comparatively reasonable.

Having lightweight and outstanding flexibility and elasticity.

The product variations are classified in SBS, SEBS, SIS, SEPS based on the difference in soft segment materials. It is usually used as a modifier of PP.

Major Product: SEPTON (kuraray) RABALON(Mitsubishi Chemical) |

| Thermoplastic Olefinic Elastomer [TPV, TPO] |

|

Popular as TSE. Thermoplastic vulcanizates (TPV) is popular for its flame retardance, but not reasonable. The hard segment of TOE is PP, so usually compounded with PP to improve recycling. Lightweight. Major Product: Thermorun™(Mitsubishi Chemical) Milastomer(Mitsui Chemical) |

| Ester [TPEE, TPC] |

|

It has high heat resistance and is less likely to become fragile in repeated bending and low-temperature environments. Both hard and soft segment are polyester. It is used for automobile and ski boots. Materials are slightly expensive. Major Product: Hytrel(DuPont, Toray) PELPRENE(TOYOBO) |

| TPVC |

| Very old and reasonable material which has quite good weather resistance. The hardness is freely adjustable with the amount since the soft segment consists of plasticizer and oil. The use is avoided, but the demand is still high. |

| Thermoplastic Polyurethane [TPU] |

|

It has been used for quite a long time compared to other elastomers. It consists of polyurethane and polyester and has high abrasion resistance and elasticity, but relatively expensive. Major Product: Miractran (Nippon Miractran) |

| Thermoplastic Polyamide Elastomer [PEBA, TPAE, TPA] |

|

It is soft but strong in repeated bending. It has oil and chemical resistance. The price is very expensive. The hard segment is nylon 12. Major Product: Polyamide Elastomer (UBE INDUSTRIES) |

| < Thermosetting and Reaction Material > | ||

|---|---|---|

| Butadiene and Isoprene | Urethane [PU] | |

| Hardened materials of butadiene and isoprene which are used as the soft segment of styrenic elastomers. Physical properties differ greatly depending on the material composition because they are mixed and made each time. It is possible to make a material with low hardness and relatively high tear strength. | Blends with a soft aliphatic urethane material and hardens it every time. Physical properties can be freely changed as in the above materials. Depending on the choice of materials, extremely soft ones can be made. | |

| < Thermosetting and Reaction Material > |

|---|

| Butadiene and Isoprene |

| Hardened materials of butadiene and isoprene which are used as the soft segment of styrenic elastomers. Physical properties differ greatly depending on the material composition because they are mixed and made each time. It is possible to make a material with low hardness and relatively high tear strength. |

| Urethane [PU] |

| Blends with a soft aliphatic urethane material and hardens it every time. Physical properties can be freely changed as in the above materials. Depending on the choice of materials, extremely soft ones can be made. |